Integrating Advanced Robotics into Modern Business Workflows

The narrative surrounding advanced robotics has dramatically shifted. It’s no longer just about massive, caged machines on an automotive assembly line.

Today’s robots are sophisticated, perceptive, and highly collaborative systems designed to work seamlessly alongside human professionals across virtually every sector.

This transformation, known as Advanced Robotics Workflow Integration, is fundamentally rewriting the playbook for operational efficiency, safety, and productivity.

This integration involves moving beyond simple, repetitive tasks to incorporating robots, powered by Artificial Intelligence (AI) and complex sensors, directly into dynamic, unpredictable business workflows.

We’re talking about systems that learn, adapt, and communicate—not just with humans, but with entire digital ecosystems like Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES).

This wave of intelligent automation isn’t just a cost-cutting measure; it’s a catalyst for entirely new business models and unprecedented levels of operational precision.

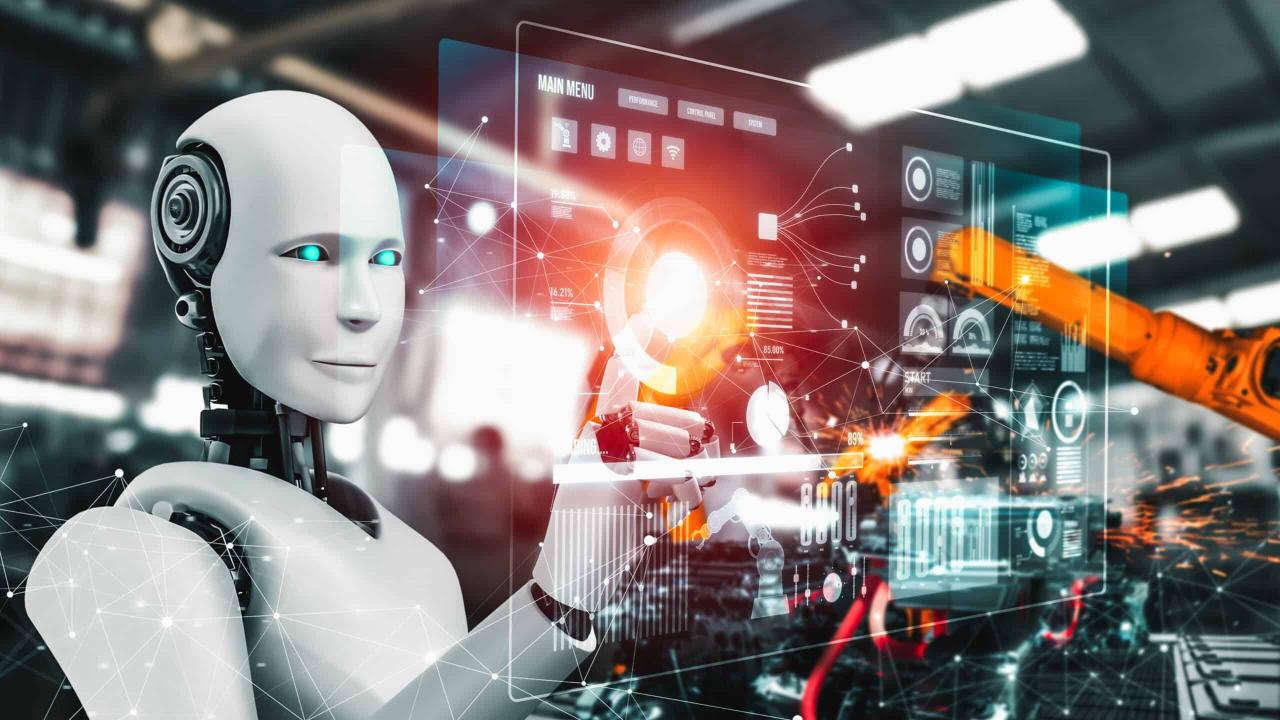

The Core Technologies Driving Seamless Integration

For robotics to transition from isolated tools to fully integrated workflow partners, several breakthrough technologies must converge. These pillars enable robots to perceive their environment, make complex decisions, and operate safely in shared spaces.

A. Collaborative Robotics (Cobots) and Human-Robot Interaction (HRI)

The most significant change is the shift from fenced-off automation to direct human-robot collaboration.

A. Force and Torque Sensing: Modern cobots are equipped with highly sensitive sensors that allow them to detect contact instantly and stop or adjust their movement, ensuring human safety in a shared workspace.

B. Intuitive Programming: Traditional robotic arms required complex coding. New systems use lead-through programming, drag-and-drop interfaces, or even gesture control, allowing shop floor personnel, not just specialized engineers, to teach the robot new tasks quickly.

C. Shared Cognitive Space: Advanced HRI research is enabling robots to predict human intent. For example, a cobot assisting in an operating room can predict the next instrument a surgeon needs based on the procedure stage, hand position, and verbal cues.

B. AI, Machine Learning, and Computer Vision

AI is the “brain” that allows a robot to handle variability—the greatest historical challenge in automation.

A. Vision-Guided Robotics: High-resolution 3D cameras and computer vision systems allow robots to recognize, locate, and manipulate irregularly shaped or moving objects, a crucial step for logistics and complex picking tasks.

B. Reinforcement Learning (RL): Robots use RL to learn optimal movement and task execution through trial and error in simulated environments before deploying those learned skills in the real world, dramatically reducing deployment time.

C. Predictive Maintenance: AI models analyze sensor data (vibration, heat, power consumption) from the robot’s components to predict failures before they occur, allowing for proactive servicing and ensuring maximum uptime, which is essential for integrated workflows.

C. Edge and Cloud Computing Infrastructure

Integrating robots into workflows requires powerful, distributed processing capabilities that go beyond the robot’s local controller.

A. Edge Processing for Real-Time Control: Time-sensitive decision-making (like collision avoidance or precise gripping) is processed locally on the robot or a nearby edge device, ensuring near-zero latency, which is critical for safety and speed.

B. Cloud for Fleet Learning and Optimization: Non-time-sensitive data, such as fleet performance logs, process efficiency metrics, and new AI models, are sent to the cloud. This allows an entire fleet of robots across different facilities to learn from the experience of a single robot (federated learning).

C. 5G and Low-Latency Networking: The roll-out of 5G and industrial Wi-Fi standards provides the high bandwidth and low latency necessary to manage hundreds of devices and exchange massive amounts of sensor data efficiently.

D. The Rise of Autonomous Mobile Robots (AMRs)

AMRs are the glue that connects stationary workstations and processes, fundamentally changing material handling and internal logistics.

A. Dynamic Path Planning: Unlike older Automated Guided Vehicles (AGVs) that follow fixed tracks, AMRs use internal maps, LiDAR, and SLAM (Simultaneous Localization and Mapping) to navigate complex, changing environments autonomously, avoiding obstacles and finding the most efficient route in real-time.

B. Fleet Management Software: Sophisticated software orchestrates entire fleets of AMRs, assigning tasks based on priority, battery level, and location, seamlessly integrating material flow into the digital MES.

C. Multi-Robot Coordination: AMRs can communicate with each other and other robotic arms to coordinate handoffs, ensuring synchronized execution of multi-step processes across large facilities.

Integrating Robotics into Vertical Workflows

The real financial and operational gain comes from customizing the integration of these technologies into industry-specific workflows. The applications are becoming highly specialized and impactful.

A. Manufacturing and Assembly Workflows

Manufacturing remains the core of robotics, but the focus is now on flexibility and customization.

A. Variable Batch Production: Robots can now quickly switch between assembling different product variants without extensive downtime, supporting high-mix, low-volume manufacturing strategies.

B. Precision Quality Control: High-speed, vision-based robots perform intricate inspection tasks, identifying microscopic defects (e.g., in electronics or delicate components) faster and more accurately than human eyes.

C. End-to-End Digital Thread: Robots, fixtures, and sensors all feed data into a unified digital model (the Digital Twin), which simulates and optimizes the entire production process before a single change is made on the factory floor.

B. Logistics and E-commerce Fulfillment Workflows

The demand for instantaneous fulfillment and personalized delivery is driving rapid robotic adoption in warehouses.

A. Automated Put-Away and Storage: Robots handle the tedious task of receiving items and placing them into the optimal storage location, often utilizing vertical space inaccessible to humans.

B. Mixed-Pallet Depalletizing: Advanced vision and grasping technologies allow robots to efficiently unload pallets containing a random assortment of different sized and weighted boxes, a major bottleneck in logistics.

C. Last-Mile Delivery Bots and Drones: Integrating AMRs and drones into the final delivery stage, optimizing routes with AI and handling the transfer of packages from the distribution hub to the consumer’s doorstep.

C. Healthcare and Life Sciences Workflows

Robots are moving into sterile, precise, and patient-facing roles in the healthcare ecosystem.

A. Automated Lab Sample Handling: Robots manage the high-throughput, contamination-sensitive process of handling, analyzing, and tracking biological samples in laboratories, accelerating drug discovery.

B. Surgical Assistance and Minimally Invasive Procedures: Robotic systems provide surgeons with enhanced dexterity, precision, and 3D visualization, enabling more complex yet less invasive surgeries.

C. Patient Monitoring and Rehabilitation: Soft robotics and specialized exoskeletons assist in physical therapy, collecting precise recovery data and adapting exercise routines in real-time.

D. Construction and Infrastructure Workflows

Robotics addresses safety concerns and labor shortages in the traditionally manual construction sector.

A. Automated Surveying and Mapping: Drones and AMRs perform site surveys and progress monitoring with greater speed and accuracy than manual methods.

B. Modular Prefabrication: Large robotic systems are used to build entire sections of buildings (like walls or bathroom pods) off-site in controlled factory environments, significantly reducing construction waste and time.

C. Dangerous Task Execution: Robots handle hazardous work like demolition, welding in confined spaces, or inspecting difficult-to-reach infrastructure, keeping human workers safe.

Operational and Strategic Benefits of Deep Integration

When advanced robotics is deeply embedded into business workflows, the benefits extend far beyond simple labor replacement. They become strategic differentiators.

A. Enhanced Flexibility and Scalability

The ability of integrated robotic systems to adapt to changing market demands is crucial for modern businesses.

A. Dynamic Capacity Adjustments: Companies can quickly scale up or down production capacity by reallocating or reprogramming robotic fleets without the lengthy hiring and training cycles required for human labor.

B. Process Agility: Robots programmed using modular software architectures can have their tasks redefined or integrated into entirely new workflows in a fraction of the time, allowing companies to pivot to new products rapidly.

B. Unprecedented Data Generation

Every movement, grip, and inspection performed by an advanced robot generates high-fidelity data, creating a powerful feedback loop.

A. Process Optimization Insights: The aggregated data highlights inefficiencies and bottlenecks in the human-robot workflow that were previously invisible, enabling continuous process improvement.

B. Supply Chain Visibility: By tracking the movement and handling of every item by AMRs and robotic arms, companies gain total, real-time visibility into their internal logistics flow.

C. Workforce Uplift and Safety Improvement

Integrating robotics is not about eliminating the workforce, but elevating it to higher-value roles.

A. Reduced Repetitive Strain Injury (RSI): Robots absorb the repetitive, physically taxing, and monotonous tasks, reducing worker fatigue and the incidence of workplace injuries.

B. Upskilling the Workforce: Workers transition from performing manual labor to managing, supervising, and programming the robotic fleet, shifting roles from “doers” to “supervisors” of high-tech systems.

C. Enhanced Ergonomics: Cobots can be programmed to assist humans with heavy lifting, effectively acting as an ergonomic extension of the human body.

Navigating the Challenges of Deep Integration

While the opportunities are vast, the path to seamless integration is fraught with technical, financial, and cultural complexities.

A. Interoperability and Standardization

The biggest technical hurdle remains the inability of robotic systems from different vendors to communicate easily.

A. Proprietary Software Barriers: Many robot manufacturers use proprietary programming languages and APIs, making it challenging to integrate them into a mixed fleet or third-party workflow software.

B. Need for Universal Communication Protocols: The industry is pushing for open standards (like ROS – Robot Operating System or OPC UA) to allow different hardware and software components to “talk” to the central ERP/MES system effortlessly.

B. Initial Capital Investment and Total Cost of Ownership (TCO)

The high upfront cost of advanced robotics can be prohibitive for small and medium-sized enterprises (SMEs).

A. Robot-as-a-Service (RaaS) Models: New subscription-based models are emerging, allowing companies to lease robotic capacity and pay based on performance or usage, shifting the TCO from a massive capital expenditure (CapEx) to a more manageable operational expenditure (OpEx).

B. Integration Expertise Gap: The cost of hiring specialized integrators and robotics engineers to design, install, and maintain the complex integrated workflow often exceeds the cost of the hardware itself.

C. Ethical and Cultural Adoption

The perception of robots “taking jobs” and the need for new ethical guidelines remain significant cultural barriers.

A. Change Management and Training: Successfully integrating robots requires a proactive change management strategy, clearly communicating the robots’ role (as assistants, not replacements) and investing heavily in retraining the existing workforce.

B. Data and Algorithmic Bias: If the AI powering the robots is trained on biased data, the robot’s decisions (e.g., in hiring/screening or quality control) could perpetuate and even amplify existing human biases.

Conclusion

Advanced Robotics Workflow Integration is no longer an optional upgrade; it is the fundamental infrastructure of the modern, competitive enterprise. The journey is about transforming isolated tasks into a continuous, intelligent “flow state” where human ingenuity and machine precision amplify each other.

The evolution we are witnessing moves automation from simple replacement (doing human tasks faster) to complex augmentation (doing things humans couldn’t do at all).

The next decade will see the complete democratization of robotics, fueled by RaaS models and intuitive programming, pushing advanced systems out of specialized factories and into local businesses, hospitals, farms, and offices.

Successful integration hinges on a core philosophy: the robotic system must be designed as an intelligent, responsive node within the company’s existing digital network. It must be able to communicate its status, receive dynamic instructions, and contribute actionable data to the enterprise brain.

Organizations that treat robots merely as hardware will lag; those that view them as intelligent data-generating partners will lead.

This deep integration promises not just a boost in profits and productivity, but a fundamental redesign of the human working experience—safer, more meaningful, and exponentially more capable.

The seamless digital thread that connects the autonomous mobile robot to the cloud, the AI engine, and the human supervisor is the key to unlocking the true potential of the next industrial era.